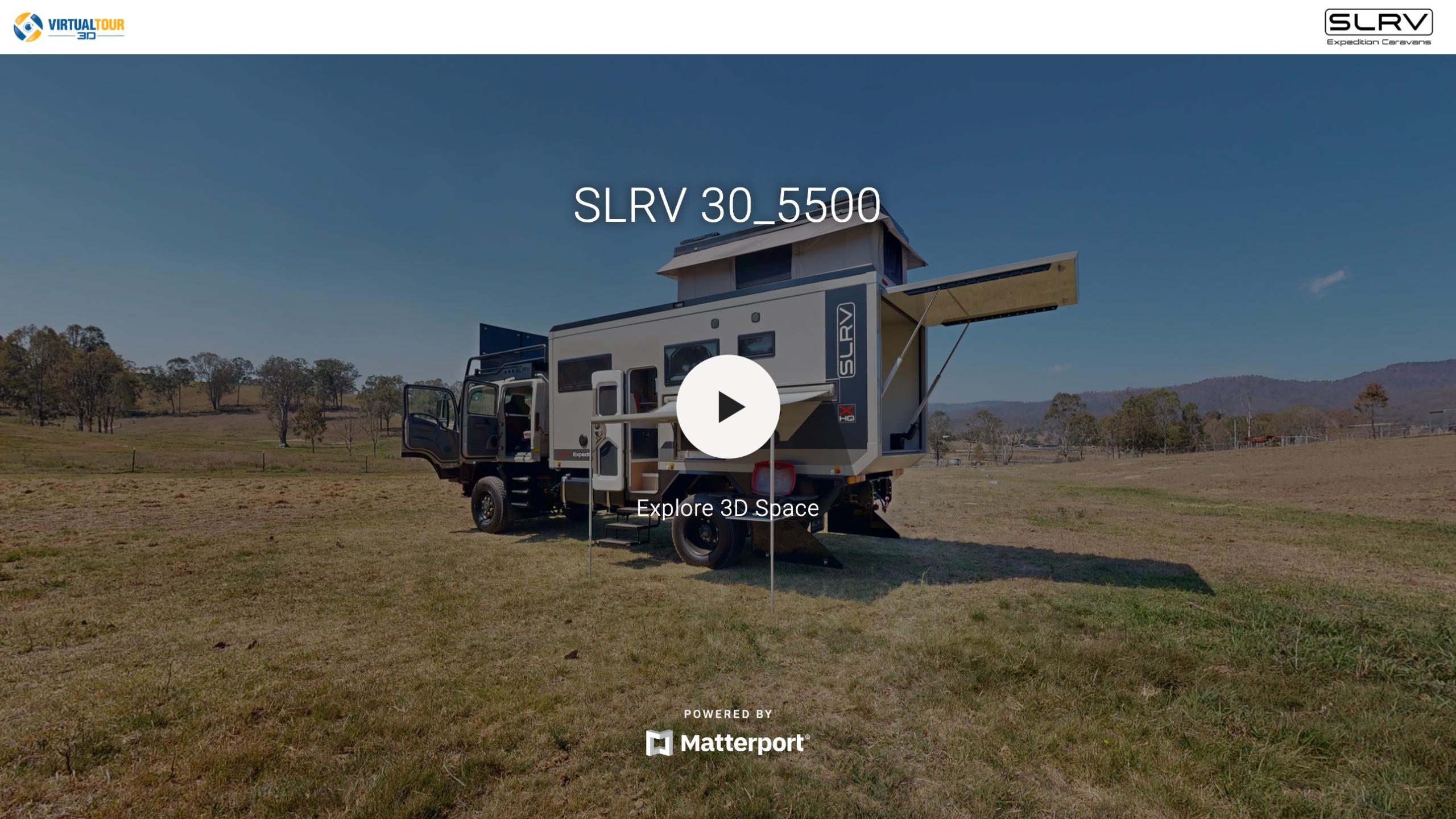

Based on the Isuzu FTS800 4x4 crew cab, this unit has plenty of seats up front, and plenty of beds in the rear.

What better way to share the touring experience!

The all new 5.5m body features an enclosed rear garage to store the spare tyre and larger items – including tables, chairs and bikes. The floorplan includes an electric lift up bed, large club lounge, galley kitchen and a separate ensuite. It’s also available with an optional ‘Super King’ electric rooftop tent with an internal access hatch and landing area. Perfect for the kids or guests, this option negates the need for bunks – allowing you to utilise the main living module for more functional areas such as the separate ensuite.

No matter the size, all SLRV interiors make the most of the available space. Intelligent designs create an open feel, while highest quality materials and appointments provide the right amount of luxury to keep you comfortable in the wilderness for longer.

Lets take a look inside…………

SLRV vehicles can be fitted with an almost endless range of features and appliances, including:

These features are seamlessly incorporated into the interior space creating an extremely spacious and comfortable atmosphere.

The electric lift up bed configuration optimises available internal space by incorporating both the bed and large club lounge into one area. Conveniently located out of the way- towards the roof, the bed can be lowered to its sleeping position at the press of a button. The extra large lounge and dining area can accommodate for the additional ‘Crew’ or just create a relaxing lounging experience for two.

Various configurations of the FTS800 feature a luxurious ‘full ensuite’ with separate shower, toilet and vanity unit. This area provides a generous amount of storage and is complimented by a solid surface benchtop with integrated sink.

The 30_5500_550 is available with an optional ‘Super King’ electric rooftop tent with an internal access hatch and landing area. Perfect for the kids or guests, this option negates the need for bunks – allowing you to utilise the main living module for more functional areas such as the separate ensuite.

No matter what your interior style is, SLRV have you covered. With a range of interior finishes including:

You’re sure to find a style that makes you feel right at home.

For remote travel, expedition vehicles are fitted with an off grid power system – for when you’re not connected to mains electricity. The power cycle can be split into 3 main stages:

Let’s have a look at how the SLRV FTS800 combines cutting-edge design and the latest technology to do just that……

SLRV are proud partners with Mastervolt – the world leaders in Lithium battery systems. The MLI Ultra series is designed to enjoy all the best properties of Lithium Ion technology in the harshest conditions. These high-performance batteries are ideal for running heavy loads for long periods and short charge times. The battery communicates with the charging system via the MasterBus network, ensuring safety and performance is maximised at all times. With up to 70% saving in space and weight, these are the ideal choice for any expedition vehicle.

This expedition vehicle is quipped as standard with three batteries – providing 690Ah @ 24 volts (1380Ah @ 12V equivalent). This system generally provides more power capacity required to run 110/240v household appliances and air conditioning, off grid, for longer periods of time. This in turn, is one of the key elements that allows SLRV vehicles to be equipped with the many ‘comforts of home’.

Much of SLRV’s power is supplied as 12V & 24V – and operates a majority of systems including LED lighting, refrigerators / freezers, pumps / plumbing, various appliances and monitoring systems.

Other appliances that we take for granted in our homes, such as induction cooktop, oven/microwave, washer/dryer, electric BBQ and air conditioner to name a few, require 110/240V power to operate. To convert 24V battery power into usable 110/240V energy for these appliances, an inverter is required. SLRV vehicles are equipped as standard, with 2 x 3000W Mastervolt inverter chargers. This system allows you to run multiple appliances at a time!

For your convenience, all SLRV vehicles feature multiple internal and external charging sockets, including:

The ability to recharge your battery system from multiple sources is vital. The nature of an expedition vehicle often requires this to be done during remote travel, where mains power isn’t readily available. Lets take a look at the ways an SLRV helps keep you charged….

When you are connected to the power grid, charging is done via the Mastervolt Combi Ultra 24/3000-150 Inverter charger.

All lithium systems use a pair of Mastervolt DC-DC chargers to receive a 200A charge from the truck.

Multiple charging sources are crucial for any expedition vehicles power system. Solar cells play an essential role in keeping your system charged when no other source is available.

SLRV expedition vehicles utilise a series of highly energy efficient 200W panels. Systems range from 1.2kW to 1.6kW – and are fitted standard on all vehicles.

Water is undoubtedly our most precious commodity when touring remotely. An Expedition Vehicle must not only hold ample water for its passengers, it has to aid in the conservation of water. This, in turn, allows you to remain out in the wilderness for longer. The SLRV team have designed a system that will do just that. Let’s have a look how it works!

To store and conserve water, the SLRV system incorporates multiple tanks – arranged in series of separate ‘cells’. By doing this, various quality water can be stored in separate tanks and accessed for specific uses – ultimately enabling you to conserve your water. This intelligent system allows you to select which tank you wish to fill by the press of a switch. Similarly, inside the vehicle, you can select which tank you want to draw from. Depending on configuration, the FTS800 holds approx 500 litres of water – suitable for long-term remote travel

Ensuring you always have a safe source of drinking water is vital. SLRV have a dedicated and totally independent drinking water system – with its own filler, tank, pump, filtration system and mixer outlet. This ensures your quality drinking water remains just that – and is ultimately conserved for extended isolated travel.

All SLRV water systems incorporate a city water entry – bypassing your tanks and allowing you to connect to the mains water supply whenever available. Pressure fillers used in the SLRV system also provide added security to your water supply.

All SLRV vehicles utilise diesel powered hot water and heater systems. These are extremely efficient and are plumbed into the trucks diesel tank. The heater works brilliantly – and the water system can supply constant hot water for your needs.

Staying out in the wilderness for longer is the name of the game. With water tanks set up in separate cells, it is possible to isolate and store water from various sources such as creeks, dams or rivers. This can be pumped into a dedicated tank using the ‘Thirsty Boy’ – and used for tasks including showering or doing a washing cycle. The Thirsty Boy can also be used on the ‘city water entry’ circuit – bypassing tanks altogether. The Thirsty Boy comes in its own ‘tough case’ with an internal pump and power supply for complete mobility. Just hook up your water hoses and away you go.

The SLRV FTS800 is constructed using premium materials and components. A three point torsion free chassis and infused composite fibreglass panelling are utilised for the ultimate function and build quality. Interior cabinetry is made to the highest standards. Take a look at what’s involved……………..

SLRV use the latest SOLIDWORKS 3D CAD software to continually develop and evaluate vehicle design. Customers receive a full 3d model and working drawings of their vehicle design, to ensure the build meets their exact requirements. By utilising this Solidworks software, a wide variety of steel and aluminium components are CNC cut and folded for precision accuracy and build quality.

The torsional ‘twist’ of the Isuzu truck chassis in extreme conditions, requires the body to be mounted using a proper ‘3 point torsion free subframe’. Conventional ‘spring mounted’ systems do not remove all the force from the body – and can potentially cause structural issues with composite panel constructions. A true 3 point torsion free system allows the body and truck chassis to twist freely and independently – removing the transfer of these forces into the motorhome body and retaining the structural integrity of the vehicle. This design also increases off-road performance by increasing the wheels ability to remain in contact with the ground over rough terrain.

30mm composite fibreglass panels are used in the construction of the FTS800 body – for ultimate strength and insulation. Unlike inferior hot glued panels, SLRV panels are fully infused – which means they are manufactured under vacuum – injecting the perfect amount of resin into the fibreglass and achieving an optimum strength to weight ratio. Imported from Sweden, the premium closed cell, self-extinguishing core material has a series of holes that allow resin to flow thru and connect the inside and outside fibreglass layers. This prevents de-lamination and adds to the overall strength of the panel. Both sides of SLRV panels are finished in gelcoat, for the maximum durability, serviceability and a brilliant finish.

All wiring throughout the SLRV FTS800 is run in conduit for protection against wear and shorting. In fact, every electrical device has its own wiring, in conduit, the entire way back to the main circuit breaker.

SLRV joinery is constructed using the highest quality materials, fixtures and fittings – and is specifically constructed for rugged off-road travel. Cabinet carcass’ are constructed from an ultralight, waterproof and fire retardant plastic material, giving high strength and durability. Cupboard and drawer fronts are finished in a high-quality ABS plastic and are complemented by soft close drawer runners and Blum overhead stays. Signature SLRV heavy duty compression latches are used throughout.

SLRV manufacture their own range of aluminium and composite panel hatch’s. Unlike mass-produced hatch’s, they are both dust and water proof and do not degrade in the sun. Composite door panels open with gas strut assist and LED lights automatically turn on inside the hatch area.

The Isuzu FTS800 (or 139-240 as it is now referred to) is an exceptional off-road truck straight out of the factory. SLRV improve upon the vehicles expedition credentials by doing some subtle but necessary modifications. Let’s have a look at what’s involved

Super single wheel and tyre combinations offer a greater footprint for improved off-road capability. The front and rear have the same track, allowing the rear to follow the compacted track of the front wheels. The larger diameter offers greater ground clearance for the vehicle and wheels can be rotated to extend the life of the tyre.

The FTS800 factory suspension is already very suitable for its intended purpose. SLRV simply add a shock absorber to the rear for increased performance and the job is done. Time to hit the ‘off’ road.

The standard steel 200L factory diesel tank is replaced with a 400L aluminium model for extended range.

A standard feature on the SLRV FTS800 is the SLRV 139-240 Expedition Roof Rack. It features a massive area for storage, tie down bars, windscreen scrub bars, spotlight mounts and an access ladder. There is also an optional roof rack box available for additional storage.

Optional accessories for the front of the Isuzu FTS800 139-240 include an alloy winch bar with bash guard and electric winch. A range of Narva LED spotlights and bars are also available to suit.

SLRV can supply and fit a rear winch bar / tow bar, with electric winch for rear recovery.

This Isuzu truck has a factory fitted air system on board. SLRV can use a take-off point to supply air fittings for tyre inflation and air tool usage.

For some of you that don’t already know, we’ve had an SLRV Expedition Vehicles YouTube channel for the last 10 […]

For those of you who haven’t purchased an INEOS Grenadier yet, now’s your chance to experience it first hand and […]

Join Australian overlanders, Heather and Garry as they leave their comfortable life behind and discover what life is really like […]